Introduction

to Mixed Bed Resin

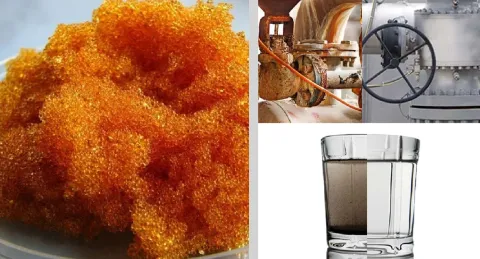

Mixed

Bed Resin is a combination of Cation and Anion Exchange Resins used for

high-purity water applications. Unlike separate cation and anion resin systems,

mixed bed resin provides superior demineralization by removing both positive

and negative ions in a single step. This makes it an essential component in

industries requiring ultrapure water, such as pharmaceuticals, power plants,

electronics manufacturing, and laboratories.

How

Does Mixed Bed Resin Work?

Mixed

Bed Resin consists of two types of resins mixed in a precise ratio:

Cation

Exchange Resin (Strong Acid Cation - SAC): Removes positively charged ions such as Calcium (Ca²⁺), Magnesium

(Mg²⁺), Sodium (Na⁺), and Iron (Fe²⁺).

Anion

Exchange Resin (Strong Base Anion - SBA): Removes negatively charged ions such as Chloride (Cl⁻), Sulfate (SO₄²⁻), Nitrate (NO₃⁻),

and Carbonate (CO₃²⁻).

As

raw water passes through the mixed bed resin, all dissolved salts and minerals

are exchanged and removed, producing high-purity demineralized water with low

conductivity.

Why

Use Mixed Bed Resin?

Mixed

Bed Resin is widely used in water treatment due to its high efficiency and

ability to produce ultrapure water. Key benefits include:

Superior

Purification: Provides a

higher level of ion removal than dual-bed (separate cation and anion) resin systems.

Ultra-Low

Conductivity Water: Reduces

water conductivity to less than 0.1 µS/cm, ensuring the highest purity.

Single

Step Demineralization:

Simplifies water treatment by combining cation and anion exchange in one unit.

Ideal

for Final Polishing: Used as a

final treatment stage after Reverse Osmosis (RO) or other purification

processes.

Types

of Mixed Bed Resin

There

are two main types of Mixed Bed Resin available:

1.

Non-Regenerable Mixed Bed Resin

- Used

in small systems such as cartridges and portable deionization units.

- Designed

for one-time use and must be replaced once exhausted.

- Commonly

used in laboratories, medical applications, and small industrial processes.

2.

Regenerable Mixed Bed Resin

- Used

in large industrial and commercial applications.

- Requires

periodic chemical regeneration to restore its ion-exchange capacity.

- Commonly

found in power plants, semiconductor manufacturing, and pharmaceutical

industries.

What

is Mixed Bed Resin Exchange Capacity?

- The

efficiency of Mixed Bed Resin is measured by its exchange capacity, which

determines how much ion removal it can perform before exhaustion.

- Exchange

Capacity of Cation Resin: Typically 1.8 to 2.0 eq/L.

- Exchange

Capacity of Anion Resin: Typically 1.0 to 1.4 eq/L.

- For

best performance, a high exchange capacity ensures maximum ion removal and

longer resin life.

How

to Regenerate Mixed Bed Resin?

Unlike

separate cation and anion resin systems, regenerating mixed bed resin is

complex because both resin types must be separated before chemical treatment.

Steps

to Regenerate Mixed Bed Resin:

1.

Separation of Cation and Anion Resins

- Backwash

the resin bed: Since cation resin is heavier, it settles at the bottom, while

anion resin floats.

- This

physical separation allows for targeted chemical regeneration.

2.

Regeneration of Cation Resin

- The

cation resin is treated with Hydrochloric Acid (HCl) (4-8%).

- This

removes calcium, magnesium, sodium, and iron ions, restoring the resin's

exchange ability.

- The

acid is flushed out with demineralized water to remove excess chemicals.

3.

Regeneration of Anion Resin

- The

anion resin is treated with Sodium Hydroxide (NaOH) (4-6%).

- This

removes chloride, sulfate, nitrate, and carbonate ions, restoring the resin’s

exchange ability.

- The

excess caustic is flushed out with demineralized water.

4.

Rinse and Remix the Resins

- Both

resins are thoroughly rinsed with high-purity water.

- After

rinsing, the resins are remixed in the correct ratio (typically 40% cation and

60% anion).

Regeneration

Frequency

- The

regeneration frequency depends on:

- Feedwater

quality

- Total

dissolved solids (TDS) load

- Required

water purity levels

- Resin

bed volume

- Typically,

industrial mixed bed resins need regeneration once their conductivity rises

above the desired level (e.g., >1 µS/cm).

Mixed

Bed Resin Life Expectancy

With

proper maintenance, mixed bed resin can last 2 to 5 years. Factors affecting

its lifespan include:

Water

Quality: High levels of

organic matter and chlorine can damage the resin.

Regeneration

Process: Incorrect chemical

dosing can degrade resin performance.

Mechanical

Wear: Frequent backwashing can

cause resin bead breakage.

Popular

Mixed Bed Resin Brands Available at Aquafit Technologies (Bangladesh)

Aquafit

Technologies offers high-quality mixed bed resins from globally recognized

manufacturers, including:

- Purolite

MB Series (UK/USA)

- Amberlite

MB Series (DuPont, USA)

- Mitsubishi

Diaion (Japan)

- Ion

Exchange (India)

- Puremagic

(Aquafit Technologies)

Conclusion

Mixed

Bed Resin is an essential technology for ultrapure water systems, offering high

efficiency in ion removal. Whether you need non-regenerable resin for

laboratory use or regenerable resin for industrial applications, choosing the

right resin type and following proper regeneration methods ensures optimal

performance and long-term cost savings.

For

high-quality Mixed Bed Resin solutions in Bangladesh, contact Aquafit

Technologies, a trusted supplier of premium water treatment resins.

Resin Manufacturer Data Sheets:

Water Treatment Handbooks & Guides:

- “Ion Exchange and Solvent Extraction” by Arup K. SenGupta

- “Water Treatment Handbook” by Degremont

- “The Nalco Water Handbook” by Nalco Chemical Company

Industry Standards & Technical Papers:

- American Water Works Association (AWWA) Standards

- Water Quality Association (WQA) Technical Bulletins

- ASTM D2187 – Standard Test Methods for Ion Exchange Resins