Introduction

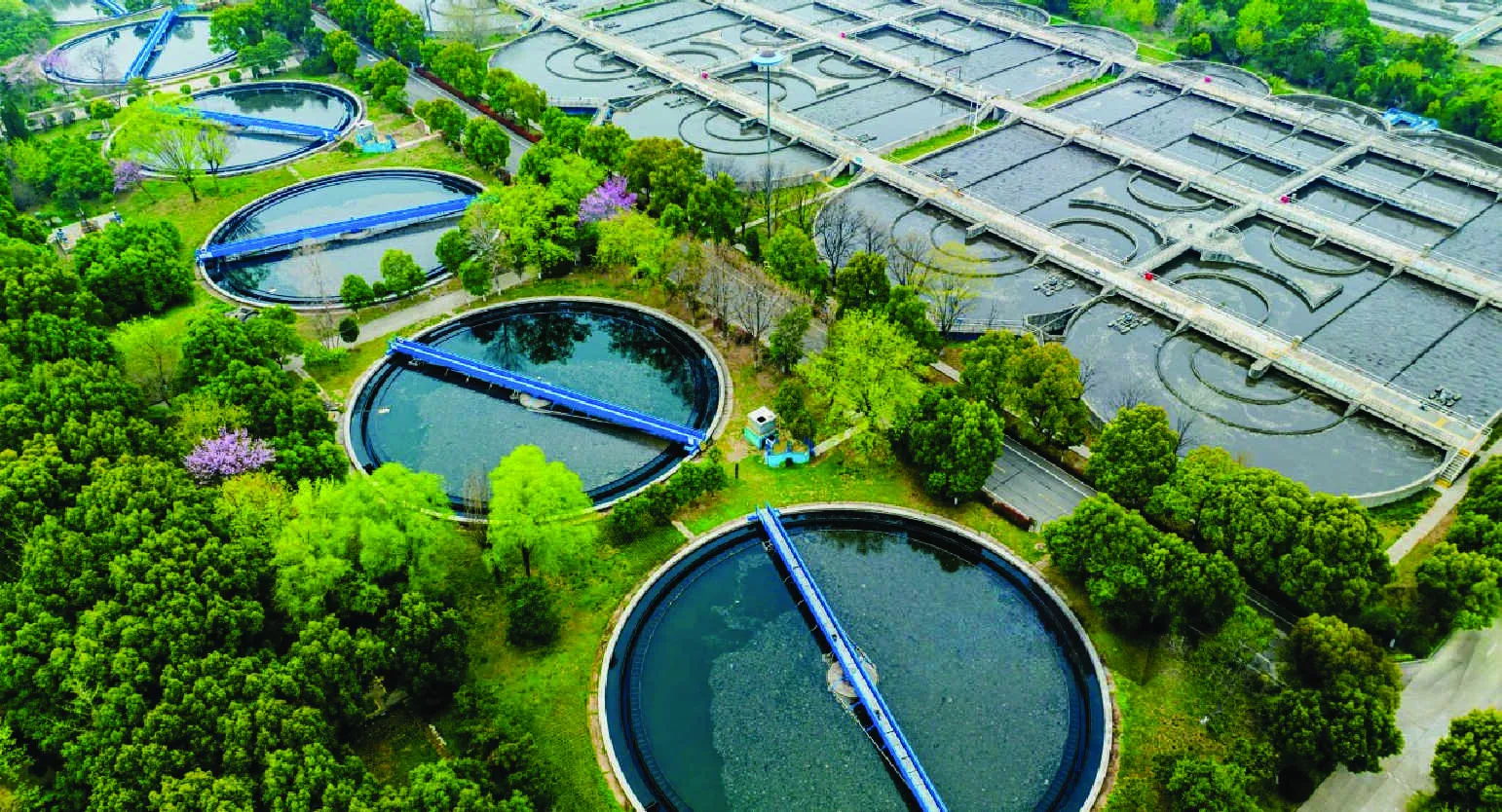

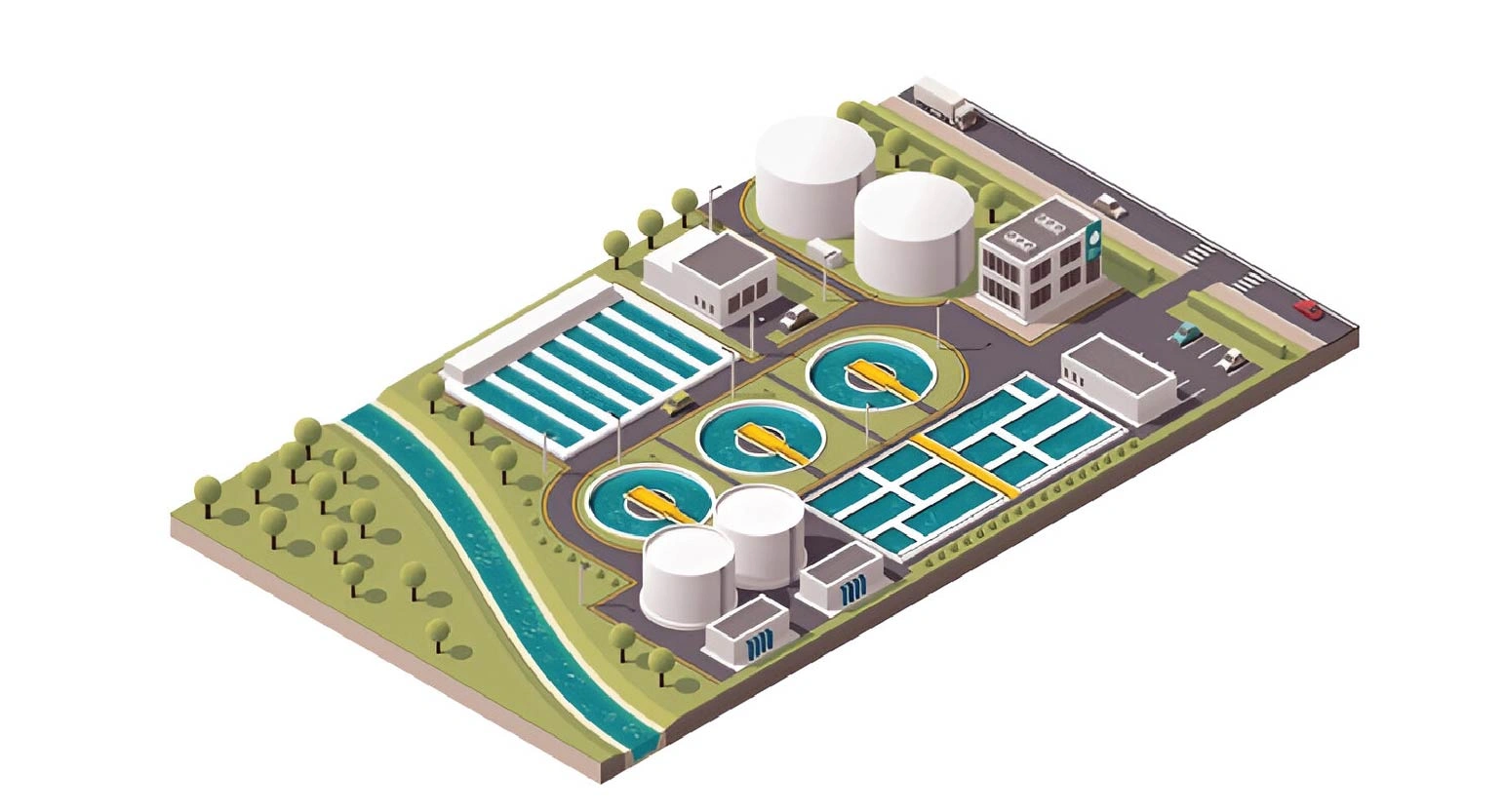

In

today's world, where industrial growth and environmental protection often seem

at odds, Effluent Treatment Plants (ETPs) play a crucial role in bridging this

gap. These facilities are the unsung heroes of our modern industrial landscape,

working tirelessly to clean and purify wastewater before it's released back

into the environment. This blog post will delve into the world of ETPs,

exploring their importance, functions, and the various processes involved in

wastewater treatment.

What

is an Effluent Treatment Plant?

An

Effluent Treatment Plant, commonly known as an ETP, is a facility designed to

purify industrial wastewater and sewage before it's discharged into the

environment. These plants are essential for managing industrial effluent,

ensuring that harmful pollutants are removed or reduced to acceptable levels

before the water is released back into natural water bodies or municipal sewage

systems.

The

Importance of ETPs in Industrial Effluent Management

ETPs are

critical for several reasons:

- They help protect the

environment from harmful pollutants

- They ensure compliance with

environmental regulations

- They contribute to water

conservation efforts

- They help maintain public

health by preventing the spread of waterborne diseases

The Wastewater Treatment Process

The treatment of industrial effluent involves several stages, each designed to remove specific types of contaminants. Let's explore these stages in detail.

Primary Treatment

The first step in the wastewater treatment process focuses on removing solid materials from the effluent.

- Screening: Large debris is removed using screens or bars

- Sedimentation: Heavier particles settle to the bottom of tanks and are removed as sludge

- Oil and grease removal: Floating materials are skimmed off the surface

Secondary Treatment: Biological Processes

After primary treatment, the wastewater undergoes biological treatment to remove dissolved and suspended organic matter.

- Activated Sludge Process: Microorganisms break down organic pollutants

- Trickling Filters: Wastewater is sprayed over a bed of rocks or plastic media covered with microorganisms

- Anaerobic Digestion: Organic matter is broken down in the absence of oxygen

Tertiary Treatment: Advanced Purification

This stage involves advanced techniques to further purify the water:

- Chemical Treatment: Coagulants and flocculants are added to remove fine particles

- Filtration: Water passes through sand, gravel, or activated carbon filters

- Disinfection: Chlorine, UV light, or ozone is used to kill remaining pathogens

Chemical Treatment of Effluent

Chemical treatment plays a vital role in the ETP process, particularly in removing specific pollutants that biological processes can't effectively handle.

Common Chemicals Used in ETPs

- Coagulants: Aluminum sulfate, ferric chloride

- pH adjusters: Lime, sodium hydroxide, sulfuric acid

- Disinfectants: Chlorine, sodium hypochlorite

Benefits of Chemical Treatment

- Removes heavy metals and other toxic substances

- Adjusts pH levels to optimal ranges for biological treatment

- Enhances the efficiency of subsequent treatment processes

Sludge Management: A Critical Aspect of ETP Operation

Sludge, the solid residue produced during wastewater treatment, requires careful handling and disposal.

Sludge Treatment Methods

- Thickening: Reducing water content to decrease volume

- Stabilization: Reducing odors and pathogens

- Dewatering: Further reducing water content for easier handling

Sludge Disposal Options

- Land application as fertilizer (if safe)

- Incineration

- Landfill disposal (as a last resort)

ETP Design and Operation: Ensuring Optimal Performance

Designing and operating an effective ETP requires careful consideration of various factors:

- Wastewater characteristics

- Treatment objectives

- Local environmental regulations

- Available space and resources

Key Considerations in ETP Design

- Flexibility to handle varying effluent loads

- Energy efficiency

- Automation and process control

- Ease of maintenance and operation

Environmental Compliance in Wastewater Treatment

Meeting regulatory standards is a critical aspect of ETP operation. Environmental compliance officers and facility managers must stay up-to-date with:

- Local, state, and federal regulations

- Discharge permit requirements

- Monitoring and reporting obligations

Best Practices for Ensuring Compliance

- Regular monitoring and testing of effluent quality

- Proper record-keeping and documentation

- Staff training on compliance requirements

- Implementing a robust environmental management system

The Future of Wastewater Treatment

As technology advances and environmental concerns grow, the future of wastewater treatment looks promising:

- Membrane technologies for more efficient filtration

- Advanced oxidation processes for removing persistent pollutants

- Resource recovery from wastewater (e.g., energy, nutrients)

- Integration of artificial intelligence for process optimization

Biological ETP

Introduction

Biological Effluent Treatment Plants (ETP) are critical in managing and treating industrial wastewater, particularly for processes involving organic waste. These systems utilize biological processes to break down pollutants, ensuring that wastewater is treated to meet environmental standards before disposal or reuse. Aquafit Technology provides cutting-edge Biological ETP solutions, designed to handle a variety of industrial effluents efficiently.

Definition

A Biological Effluent Treatment Plant (ETP) employs microorganisms to degrade organic pollutants in wastewater. The treatment relies on the natural metabolic processes of bacteria and other microbes to convert organic waste into less harmful substances, such as carbon dioxide and water. Biological ETPs are essential for industries that generate high volumes of organic wastewater, including food and beverage, pharmaceuticals, and textiles.

Types of Biological ETP

- Activated Sludge Process:

- How It Works: This process involves aerating the wastewater in a tank to encourage the growth of microorganisms that consume organic pollutants. The treated water is then separated from the activated sludge, which is recycled back into the system.

- Applications: Widely used in municipal and industrial wastewater treatment due to its effectiveness in removing organic matter.

- Trickling Filter:

- How It Works: Wastewater is distributed over a bed of microbial-covered media, where microorganisms degrade organic matter as the water flows through.

- Applications: Suitable for small to medium-sized treatment facilities and industries with moderate organic waste loads.

- Sequential Batch Reactor (SBR):

- How It Works: This system treats wastewater in batches, allowing for different stages of treatment (e.g., aeration, settling) to occur in the same tank.

- Applications: Ideal for facilities with varying wastewater flows and loads.

Effects of Biological ETP

- Reduces Organic Load: Effectively decreases the concentration of organic pollutants in wastewater, reducing its environmental impact.

- Improves Water Quality: Treats wastewater to meet regulatory standards, ensuring that it is safe for discharge or reuse.

- Cost-Effective: Biological treatment processes are generally more economical compared to chemical or physical methods.

Conclusion

Biological ETPs are a vital component of modern wastewater management, providing an effective and sustainable solution for treating organic waste. These systems utilize natural processes to produce cleaner, safer effluents, benefiting both the environment and industry.

Aquafit Technology offers top-of-the-line Biological ETP solutions tailored to your specific needs, ensuring optimal performance and compliance with environmental standards. Trust us to deliver the best in biological wastewater treatment technology.

Biochemical

ETP

Introduction

Biochemical

Effluent Treatment Plants (ETP) are specialized systems designed to treat

industrial wastewater through biochemical processes. These plants leverage the

natural ability of microorganisms to break down organic pollutants, ensuring

that wastewater is treated effectively to meet environmental regulations.

Aquafit Technology offers advanced Biochemical ETP solutions, tailored to meet

the diverse needs of industries in Bangladesh.

Definition

Biochemical

Effluent Treatment Plants (ETP) utilize biochemical reactions to decompose organic

contaminants in wastewater. This method harnesses the activity of bacteria and

other microorganisms to convert complex organic substances into simpler, less

harmful compounds like carbon dioxide and water. Biochemical ETPs are

particularly effective for industries with high organic waste content, such as

food processing, pharmaceuticals, and chemical manufacturing.

Types

of Biochemical ETP

- Activated Sludge

Process:

- How It Works: This process

involves aerating wastewater in a large tank to promote the growth of

microorganisms. These microbes consume organic pollutants, which are then

separated from the treated water.

- Applications: Commonly used for

treating municipal and industrial wastewater due to its efficiency in

removing organic matter.

- Rotating Biological

Contactors (RBC):

- How It Works: Wastewater is

passed over rotating discs coated with a microbial biofilm. As the discs

rotate, microorganisms break down organic pollutants from the wastewater.

- Applications: Suitable for

small to medium-sized treatment plants, providing efficient treatment

with lower energy consumption.

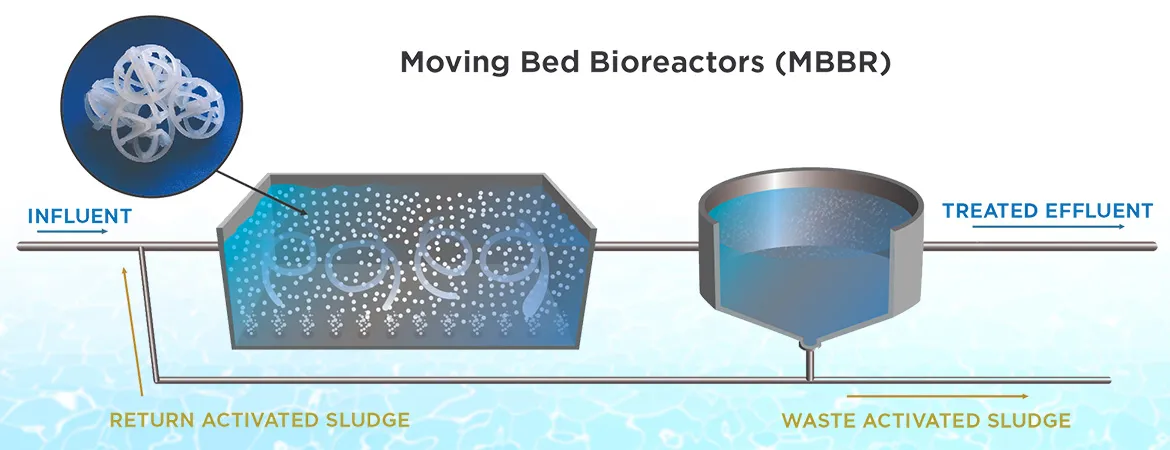

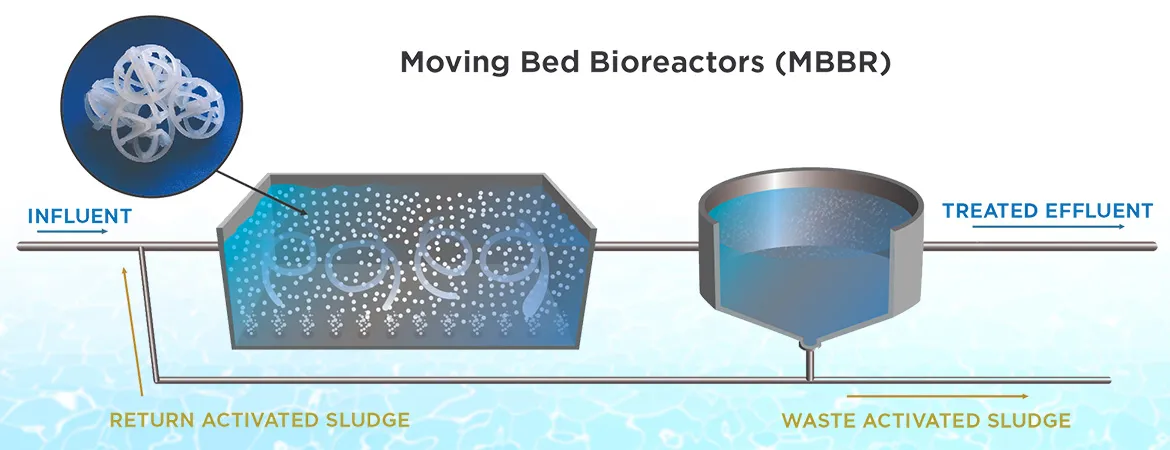

- Moving Bed Biofilm

Reactor (MBBR):

- How It Works: This system uses

plastic carriers that support a biofilm of microorganisms. Wastewater

flows through the reactor, and the biofilm degrades organic matter.

- Applications: Ideal for

facilities with fluctuating wastewater loads and where space is limited.

Effects

of Biochemical ETP

- Reduces Organic

Load:

Effectively lowers the concentration of organic contaminants, making the

wastewater safer for discharge or reuse.

- Enhances Water

Quality:

Produces treated water that meets regulatory standards, helping industries

comply with environmental regulations.

- Cost-Effective and

Sustainable:

Biochemical treatment processes are generally more economical and

environmentally friendly compared to chemical alternatives.

Conclusion

Biochemical

ETPs offer an effective and sustainable solution for treating industrial

wastewater, utilizing natural biological processes to ensure high-quality

effluents. These systems are essential for industries that produce high volumes

of organic waste, providing both environmental and economic benefits.

Aquafit

Technology provides state-of-the-art Biochemical ETP systems, designed to meet

the specific needs of various industries in Bangladesh. Trust us to deliver the

best in biochemical wastewater treatment technology, ensuring your operations

are both efficient and compliant with environmental standards.

MBBR

Technology

Introduction

Moving

Bed Biofilm Reactor (MBBR) technology is a cutting-edge solution for wastewater

treatment that offers enhanced efficiency and flexibility. This technology

leverages the natural processes of microorganisms to degrade organic

contaminants, making it an ideal choice for a range of industrial and municipal

applications. Aquafit Technology provides state-of-the-art MBBR systems,

tailored to meet the specific needs of wastewater treatment in Bangladesh.

Definition

Moving

Bed Biofilm Reactor (MBBR)

is a biological wastewater treatment technology that uses suspended plastic

carriers to support the growth of a biofilm of microorganisms. These

microorganisms break down organic pollutants as wastewater flows through the

reactor. MBBR systems combine the benefits of both activated sludge and biofilm

technologies, providing a highly efficient and compact treatment solution.

How

MBBR Technology Works

- Plastic Carriers: The MBBR system

contains plastic media with high surface area, which provides a habitat

for microorganisms to grow. These carriers are kept in constant motion by

aeration or mixing, ensuring that the biofilm remains active and

effective.

- Biological

Treatment:

As wastewater flows through the reactor, the microorganisms on the plastic

carriers metabolize organic pollutants, converting them into simpler

compounds such as carbon dioxide and water.

- Separation: After treatment,

the water is separated from the biomass. The treated effluent is typically

of high quality, meeting regulatory standards for discharge or reuse.

Types

of MBBR Systems

- Single-Stage MBBR: Used for

straightforward applications where primary and secondary treatment occur

in the same reactor, ideal for smaller facilities or less complex

wastewater.

- Two-Stage MBBR: Involves separate

reactors for primary and secondary treatment, providing greater

flexibility and efficiency for handling varying wastewater loads and

compositions.

Benefits

of MBBR Technology

- High Efficiency: MBBR systems offer

high treatment efficiency, effectively removing organic contaminants and

improving water quality.

- Compact Design: The use of plastic

carriers allows for a smaller footprint compared to traditional treatment

methods, making MBBR systems suitable for facilities with limited space.

- Flexible Operation: MBBR technology

can easily adapt to changes in wastewater flow and composition, offering a

scalable solution for various applications.

- Low Maintenance: MBBR systems

require minimal maintenance, with the plastic carriers providing a durable

and long-lasting support structure for the biofilm.

Conclusion

MBBR

technology is an advanced and versatile solution for wastewater treatment,

combining the benefits of biofilm and activated sludge processes. Its high

efficiency, compact design, and flexibility make it an excellent choice for a

wide range of applications.

Aquafit

Technology offers cutting-edge MBBR systems tailored to meet the specific needs

of wastewater treatment in Bangladesh. Our solutions ensure optimal performance

and compliance with environmental standards, helping you achieve the highest

quality treated water.

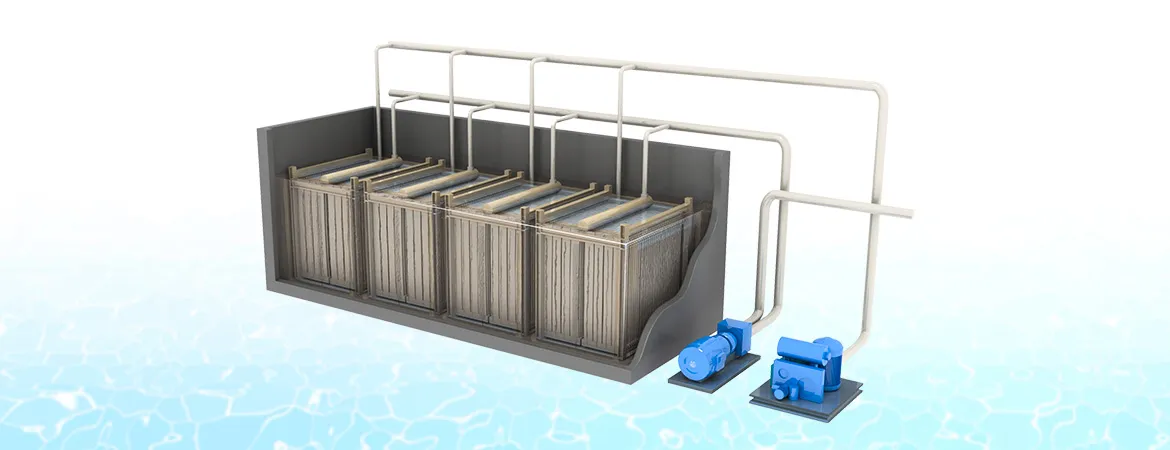

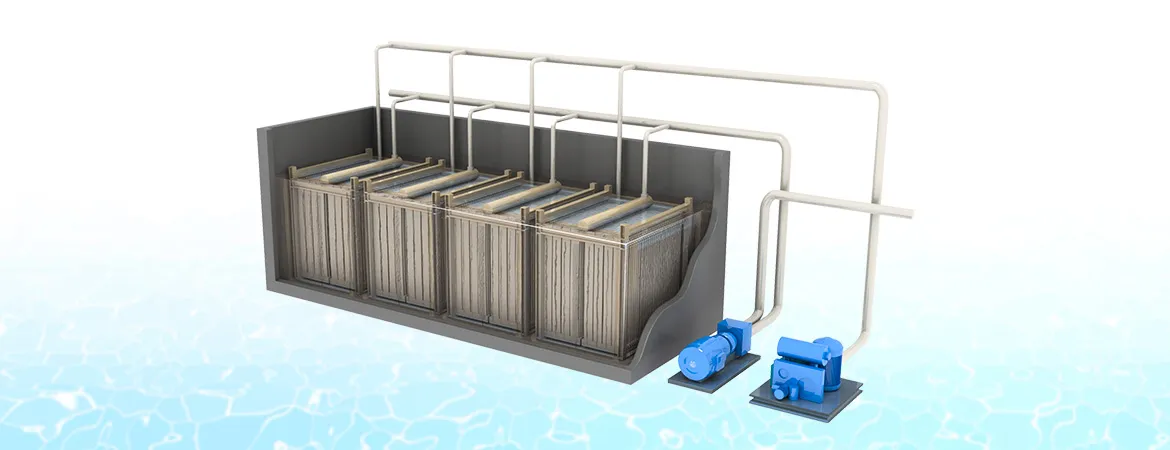

MBR

Technology

Introduction

Membrane

Bioreactor (MBR) technology is at the forefront of wastewater treatment

innovation, combining biological treatment processes with membrane filtration

to achieve superior water quality. MBR systems are known for their high

efficiency, compact footprint, and ability to produce high-quality effluent.

Aquafit Technology offers advanced MBR solutions, designed to meet the

demanding requirements of wastewater treatment in Bangladesh.

Definition

Membrane

Bioreactor (MBR)

technology integrates biological treatment processes with membrane filtration

to simultaneously remove organic pollutants and separate solids from

wastewater. The system uses a combination of activated sludge and membrane

filtration to achieve high-quality treated water that meets or exceeds

regulatory standards.

How

MBR Technology Works

- Biological

Treatment:

Wastewater is first treated biologically using activated sludge, where

microorganisms break down organic contaminants. This process occurs in a

bioreactor tank.

- Membrane

Filtration:

After biological treatment, the mixed liquor (a mixture of treated water

and microorganisms) passes through a membrane filtration unit. The

membranes, typically made from materials like polyvinylidene fluoride

(PVDF) or ceramic, filter out suspended solids, bacteria, and other

contaminants, producing a clear and high-quality effluent.

- Effluent Quality: The treated water,

or permeate, is of high quality and can be safely discharged or reused for

various applications, including industrial processes, irrigation, and even

potable use in some cases.

Types

of MBR Systems

- Submerged Membrane

Bioreactors:

In this system, membranes are immersed directly in the bioreactor tank.

The mixed liquor flows through the membranes for filtration, and the clean

permeate is collected.

- External Membrane

Bioreactors:

Here, membranes are located outside the bioreactor tank. The mixed liquor

is pumped through the membrane module for filtration before returning to

the bioreactor.

Benefits

of MBR Technology

- High-Quality

Effluent:

MBR systems produce effluent with very low levels of suspended solids and

contaminants, making it suitable for discharge or reuse in sensitive

environments.

- Compact Design: The integration of

biological treatment with membrane filtration allows MBR systems to have a

smaller footprint compared to traditional treatment methods, making them

ideal for facilities with space constraints.

- Reduced Sludge

Production:

MBR technology reduces the volume of excess sludge generated, leading to

lower disposal costs and improved operational efficiency.

- Flexibility and

Scalability:

MBR systems can be easily scaled to accommodate varying wastewater flows

and treatment requirements, providing a versatile solution for diverse

applications.

Conclusion

MBR

technology represents a significant advancement in wastewater treatment,

offering high efficiency, compact design, and exceptional effluent quality. Its

ability to integrate biological and filtration processes makes it an ideal

choice for applications where superior water quality is essential.

Aquafit

Technology provides state-of-the-art MBR systems tailored to the specific needs

of wastewater treatment in Bangladesh. Our solutions ensure optimal performance

and compliance with environmental standards, helping you achieve the highest

quality treated water.

Electrolysis

Technology

Introduction

Electrolysis

technology is a transformative process used in various industries for water

treatment, purification, and disinfection. By applying electrical current to

water, electrolysis facilitates the breakdown of contaminants and the

generation of useful byproducts, making it an efficient and versatile

technology. Aquafit Technology offers advanced electrolysis solutions, designed

to meet the specific needs of water treatment in Bangladesh.

Definition

Electrolysis is a chemical process

that uses electrical current to drive a non-spontaneous chemical reaction. In

the context of water treatment, electrolysis involves passing an electric

current through water to produce various beneficial effects, including the generation

of disinfecting agents and the removal of contaminants.

How

Electrolysis Technology Works

- Electrolytic Cells: Water is placed in

an electrolytic cell, which contains two electrodes—an anode and a

cathode. When an electrical current is applied, it causes a chemical

reaction at the electrodes.

- Production of

Disinfectants:

At the anode, water undergoes oxidation to produce chlorine, ozone, or

other disinfecting agents. These substances effectively kill bacteria,

viruses, and other microorganisms. At the cathode, reduction reactions may

occur, which can help remove contaminants from the water.

- Contaminant

Removal:

Electrolysis can break down organic contaminants, precipitate heavy

metals, and assist in the removal of impurities, resulting in cleaner and

safer water.

Types

of Electrolysis Systems

- Chlorine Generation

Systems:

- How It Works: Chlorine is

produced at the anode, which is then used for disinfecting water. This

method is commonly employed in water treatment plants for municipal and

industrial applications.

- Ozone Generation

Systems:

- How It Works: Ozone is

generated from oxygen and used as a powerful disinfectant and oxidizing

agent. Ozone systems are effective in removing organic contaminants and

improving water quality.

- Electrocoagulation

Systems:

- How It Works:

Electrocoagulation uses electrical current to induce coagulation and

flocculation processes, which help in the removal of suspended solids,

heavy metals, and other pollutants.

Benefits

of Electrolysis Technology

- Effective

Disinfection:

Electrolysis generates powerful disinfecting agents like chlorine and

ozone, which effectively kill microorganisms and purify water.

- Environmentally

Friendly:

Electrolysis does not produce harmful byproducts, making it a clean and

sustainable solution for water treatment.

- Versatile

Applications:

Electrolysis can be used for a range of applications, including municipal

water treatment, industrial processes, and wastewater treatment.

- Cost-Effective: With minimal

chemical requirements and low operational costs, electrolysis technology

offers an economical solution for maintaining high water quality.

Conclusion

Electrolysis

technology represents a significant advancement in water treatment, offering

effective disinfection, contaminant removal, and environmentally friendly

solutions. Its versatility and efficiency make it an ideal choice for a wide

range of applications.

Aquafit

Technology provides state-of-the-art electrolysis systems tailored to the

specific needs of water treatment in Bangladesh. Our solutions ensure optimal

performance and compliance with environmental standards, helping you achieve

the highest quality water.

Zero

Liquid Discharge (ZLD) Plants for ETP

Introduction

Zero

Liquid Discharge (ZLD) plants are advanced systems designed to treat and reuse

wastewater, achieving a state where no liquid waste is discharged into the environment.

In the context of Effluent Treatment Plants (ETP), ZLD technology plays a

crucial role in maximizing water reuse and minimizing environmental impact.

Aquafit Technology provides cutting-edge ZLD solutions tailored to enhance the

sustainability and efficiency of wastewater treatment processes in Bangladesh.

Definition

Zero

Liquid Discharge (ZLD)

refers to a wastewater management process where all the treated water is

recovered and reused, and no liquid waste is discharged into the environment.

This approach involves the complete treatment and recycling of wastewater,

ensuring that only solid residues are left behind, which can often be further

processed or disposed of in an environmentally responsible manner.

How

ZLD Plants Work

- Pre-Treatment: The wastewater

from ETP is first subjected to pre-treatment processes to remove larger

solids and contaminants. This step often includes filtration,

sedimentation, and chemical dosing.

- Advanced Treatment: Following

pre-treatment, advanced technologies such as Reverse Osmosis (RO),

Electrodialysis (ED), and Evaporation are used to further purify the

water. These methods concentrate contaminants and recover high-quality

water.

- Concentration and

Crystallization:

The concentrated waste from the advanced treatment processes is then

subjected to evaporation or crystallization. This step converts the

concentrated waste into solid residues and pure water.

- Water Reuse: The purified water

recovered from the ZLD process is reused within the industrial facility

for various applications, such as cooling, cleaning, and other processes.

This reduces the need for fresh water and minimizes wastewater disposal.

Benefits

of ZLD Plants

- Environmental

Protection:

ZLD plants eliminate liquid waste discharge, significantly reducing the

environmental impact and contributing to pollution prevention.

- Resource

Efficiency:

By recovering and reusing treated water, ZLD systems reduce the demand for

fresh water resources, enhancing overall resource efficiency.

- Regulatory

Compliance:

ZLD technology helps industries meet stringent environmental regulations

and discharge standards, avoiding potential fines and penalties.

- Cost Savings: Although the

initial investment in ZLD technology can be high, long-term savings are

achieved through reduced water procurement costs and minimized waste

disposal expenses.

Conclusion

Zero

Liquid Discharge (ZLD) plants represent a significant advancement in wastewater

management, offering a sustainable solution for treating and reusing

ETP-treated water. By recovering and reusing virtually all treated water, ZLD

systems contribute to environmental protection and resource efficiency.

Aquafit

Technology provides state-of-the-art ZLD solutions designed to optimize

wastewater reuse and enhance sustainability. Our expertise ensures that your

ETP-treated water is managed efficiently, helping you achieve zero liquid

discharge and meet your environmental goals.

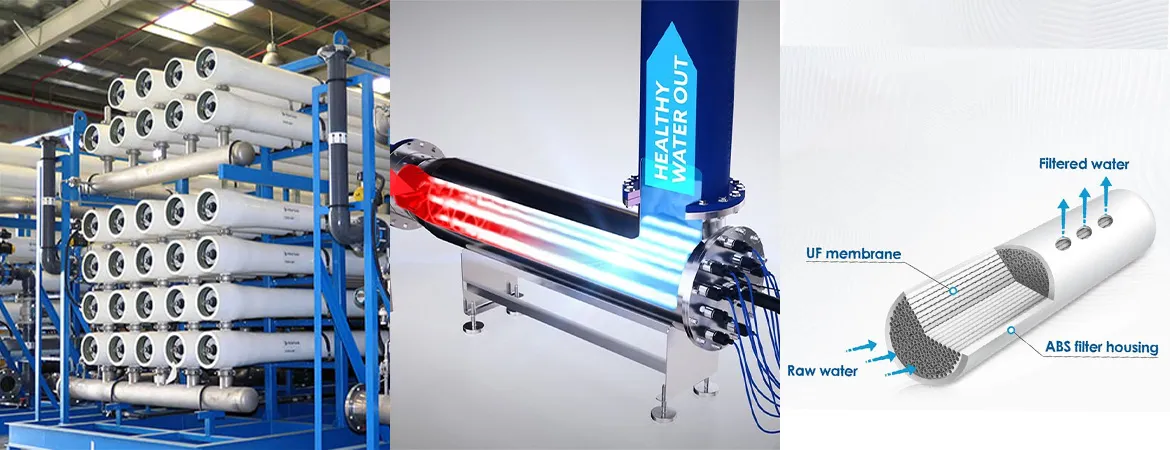

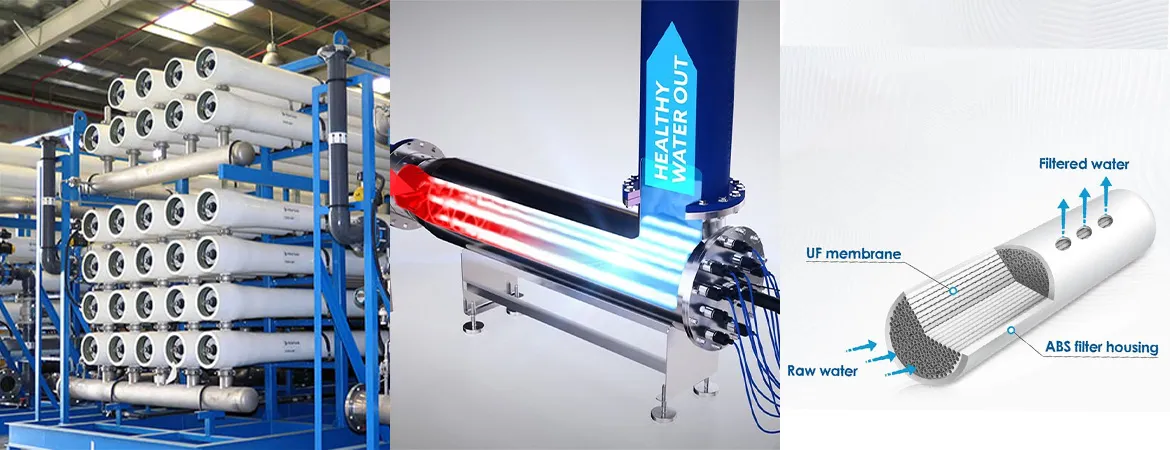

RO,

UF, and UV Technologies for Effluent Treatment Plants (ETP)

Introduction

Effluent

Treatment Plants (ETP) are essential for managing and treating industrial

wastewater, ensuring that it meets environmental standards before discharge or

reuse. Among the advanced technologies used in ETPs, Reverse Osmosis (RO),

Ultrafiltration (UF), and Ultraviolet (UV) disinfection play crucial roles in

achieving high-quality treated water. Aquafit Technology offers

state-of-the-art solutions integrating RO, UF, and UV technologies to enhance

the effectiveness of wastewater treatment processes in Bangladesh.

Reverse

Osmosis (RO)

Definition: Reverse Osmosis (RO) is

a filtration process that uses a semi-permeable membrane to remove contaminants

from water. Under high pressure, water is forced through the membrane, which

retains dissolved solids, organic compounds, and other impurities, allowing

only clean water to pass through.

How

It Works:

- High Pressure: Water is

pressurized to overcome the natural osmotic pressure, forcing it through

the RO membrane.

- Contaminant

Removal:

The membrane filters out contaminants including salts, metals, and organic

compounds, producing purified water.

Benefits:

- High Purity: RO effectively

removes a wide range of contaminants, ensuring high-quality treated water.

- Versatile: Suitable for

various applications, including industrial processes and potable water

production.

- Efficient: Reduces the need

for chemical treatments and minimizes waste production.

Ultrafiltration

(UF)

Definition: Ultrafiltration (UF) is

a membrane filtration process that separates suspended solids, colloids, and

macromolecules from water. UF membranes have larger pore sizes compared to RO

membranes, allowing them to filter out larger particles while permitting water

and smaller molecules to pass through.

How

It Works:

- Membrane

Filtration:

Water flows through the UF membrane, which retains particles and

contaminants larger than the membrane’s pore size.

- Filtrate

Collection:

Clean water, free from larger impurities, is collected as the permeate.

Benefits:

- Effective Filtration: UF removes

suspended solids, bacteria, and some viruses, producing clean water with

minimal fouling.

- Low Energy

Consumption:

Requires less pressure than RO, leading to lower operational costs.

- Pre-Treatment: Often used as a

pre-treatment for RO systems to reduce membrane fouling and extend

membrane life.

Ultraviolet

(UV) Disinfection

Definition: Ultraviolet (UV)

disinfection is a water treatment process that uses UV light to kill or

inactivate microorganisms. UV light disrupts the DNA of bacteria, viruses, and

other pathogens, rendering them unable to reproduce and cause harm.

How

It Works:

- UV Exposure: Water flows

through a UV chamber where it is exposed to UV light.

- Microbial

Inactivation:

The UV light penetrates the cells of microorganisms, causing DNA damage

and inactivating them.

Benefits:

- Effective

Disinfection:

UV technology provides a chemical-free method to kill pathogens, ensuring

safe water.

- Immediate Action: Offers rapid

disinfection with no residual effects or byproducts.

- Low Maintenance: Requires minimal

maintenance and operating costs compared to chemical disinfection methods.

Conclusion

Integrating

RO, UF, and UV technologies in Effluent Treatment Plants (ETP) enhances the

effectiveness of wastewater treatment, ensuring high-quality, safe, and

compliant water. Each technology offers unique benefits, from high purity and

effective filtration to reliable disinfection.

Aquafit

Technology provides advanced RO, UF, and UV solutions tailored to your specific

wastewater treatment needs. Our expertise ensures optimal performance and

compliance with environmental standards, helping you achieve the highest

quality treated water.

ETP

Plant for Garments Washing/Laundry

Introduction

Effluent

Treatment Plants (ETP) tailored for garments washing and laundry operations are

essential for managing the significant volumes of wastewater generated in the

textile industry. These plants ensure that wastewater is treated effectively to

meet environmental standards before discharge or reuse. Aquafit Technology

provides advanced ETP solutions specifically designed for the unique needs of

the garments washing and laundry sector in Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for garments washing and laundry are specialized systems designed to treat

wastewater generated during the cleaning and dyeing of textiles. These plants

use a combination of physical, chemical, and biological processes to remove

contaminants, including dyes, chemicals, and organic matter, from the

wastewater.

How

ETP Plants for Garments Washing/Laundry Work

- Pre-Treatment:

- Screening and

Filtration:

Large solids and debris are removed through screening and filtration

processes.

- Chemical Dosing: Coagulants and

flocculants are added to facilitate the aggregation of fine particles and

impurities, making them easier to remove.

- Primary Treatment:

- Sedimentation: Suspended solids

and particulate matter are settled out in sedimentation tanks, reducing

the load on subsequent treatment stages.

- Secondary

Treatment:

- Biological

Treatment:

Microorganisms break down organic contaminants in aerobic or anaerobic

reactors, such as Activated Sludge Process (ASP) or Moving Bed Biofilm

Reactor (MBBR).

- Advanced

Filtration:

Ultrafiltration (UF) or Reverse Osmosis (RO) may be used for further

purification, removing smaller contaminants and improving water quality.

- Tertiary Treatment:

- Disinfection: Ultraviolet (UV)

light or other disinfection methods are employed to kill any remaining

microorganisms, ensuring the treated water is safe for discharge or

reuse.

- Sludge Management:

- Dewatering and

Disposal:

The sludge generated during the treatment processes is dewatered and

properly disposed of or treated further to minimize environmental impact.

Benefits

of ETP Plants for Garments Washing/Laundry

- Compliance: Ensures that

wastewater meets regulatory standards before discharge, avoiding legal

issues and potential fines.

- Environmental

Protection:

Reduces the release of harmful pollutants and dyes into the environment,

protecting local water bodies and ecosystems.

- Resource

Efficiency:

Treated water can be reused within the facility for various processes,

reducing freshwater consumption and operational costs.

- Operational

Efficiency:

Efficient treatment systems improve the overall sustainability and

operational efficiency of the laundry or garment washing process.

Conclusion

Effluent

Treatment Plants (ETP) for garments washing and laundry are vital for managing

wastewater effectively, ensuring compliance with environmental regulations, and

promoting sustainability. These plants utilize a combination of physical,

chemical, and biological processes to achieve high-quality treated water.

Aquafit

Technology offers state-of-the-art ETP solutions specifically designed for the

garments washing and laundry industry. Our advanced systems ensure optimal

performance, regulatory compliance, and environmental protection, helping you

achieve efficient and sustainable wastewater management.

ETP

Plant for Hospitals

Introduction

Effluent

Treatment Plants (ETP) for hospitals are crucial in managing the complex and

potentially hazardous wastewater generated by medical facilities. Hospitals

produce wastewater that contains a range of contaminants, including

pharmaceuticals, chemicals, and biological agents, which require specialized

treatment to ensure safe disposal or reuse. Aquafit Technology provides advanced

ETP solutions tailored to the unique needs of healthcare facilities in

Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for hospitals are specialized systems designed to treat and manage wastewater

generated from medical and healthcare activities. These plants use a

combination of physical, chemical, and biological processes to remove

contaminants and ensure that treated water meets environmental regulations.

How

ETP Plants for Hospitals Work

- Pre-Treatment:

- Screening and

Filtration:

Initial stages involve removing large solids and debris from the

wastewater through screens and filters.

- Chemical Dosing: Chemicals such as

coagulants and flocculants are added to help aggregate and remove fine

particles and contaminants.

- Primary Treatment:

- Sedimentation: In sedimentation

tanks, suspended solids settle out from the wastewater, reducing the load

on subsequent treatment stages.

- Secondary

Treatment:

- Biological

Treatment:

Microorganisms break down organic matter in aerobic or anaerobic

reactors, such as Activated Sludge Process (ASP) or Moving Bed Biofilm

Reactor (MBBR), effectively treating the wastewater.

- Advanced

Filtration:

Processes such as Ultrafiltration (UF) or Reverse Osmosis (RO) may be

used for further purification, removing smaller contaminants and

improving water quality.

- Tertiary Treatment:

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems are employed to kill any remaining

pathogens, ensuring that the treated water is safe for discharge or

reuse.

- Special

Considerations:

- Pharmaceuticals

and Chemicals:

Additional treatment steps, such as advanced oxidation processes (AOP) or

activated carbon adsorption, may be required to address pharmaceutical

residues and chemical pollutants.

- Sludge Management: The sludge

generated during treatment is dewatered and properly disposed of or

further treated to minimize environmental impact.

Benefits

of ETP Plants for Hospitals

- Compliance: Ensures that

hospital wastewater meets stringent regulatory standards before discharge,

avoiding legal issues and potential fines.

- Public Health

Protection:

Effectively removes harmful pathogens, pharmaceuticals, and chemicals,

protecting public health and the environment.

- Environmental

Stewardship:

Minimizes the environmental impact of hospital wastewater by reducing

pollutants and ensuring safe disposal or reuse.

- Operational

Efficiency:

Enhances the sustainability and efficiency of hospital operations by

providing a reliable wastewater treatment solution.

Conclusion

Effluent

Treatment Plants (ETP) for hospitals are essential for managing the complex and

potentially hazardous wastewater produced by healthcare facilities. By

employing a combination of physical, chemical, and biological treatment

processes, these plants ensure high-quality treated water that meets regulatory

standards.

Aquafit

Technology provides cutting-edge ETP solutions tailored to the specific needs

of hospitals. Our advanced systems ensure optimal performance, regulatory

compliance, and environmental protection, helping you achieve effective and

sustainable wastewater management.

ETP Plant for Pharmaceuticals

Introduction

Effluent Treatment Plants (ETP) tailored for the pharmaceutical industry are essential for managing the complex wastewater generated during pharmaceutical manufacturing processes. The wastewater from pharmaceutical facilities often contains a variety of contaminants, including active pharmaceutical ingredients(APIs), solvents, and other chemicals that require specialized treatment to ensure safe disposal or reuse. Aquafit Technology offers state-of-the-art ETP solutions designed to address the unique challenges of pharmaceutical wastewater in Bangladesh.

Definition

Effluent Treatment Plants (ETP) for pharmaceuticals are specialized systems designed to treat waste water generated by pharmaceutical manufacturing operations. These plants utilize a combination of physical, chemical, and biological processes to remove contaminants and ensure that the treated water meets environmental regulations.

How ETP Plants for Pharmaceuticals Work

- Pre-Treatment:

- Screening and Filtration: Large solids and particulate matter are removed through screening and filtration processes.

- Chemical Dosing: Coagulants and flocculants are added to facilitate the aggregation of fine particles and contaminants, making them easier to remove.

- Primary Treatment:

- Sedimentation: Suspended solids are settled out in sedimentation tanks, reducing the load on subsequent treatment stages.

- Secondary Treatment:

- Biological Treatment: In aerobic or anaerobic reactors, microorganisms break down organic contaminants, including pharmaceuticals, using processes like Activated Sludge Process (ASP) or Moving Bed Biofilm Reactor (MBBR).

- Advanced Filtration: Technologies such as Ultrafiltration (UF) or Reverse Osmosis (RO) may be employed to further purify the water, removing smaller contaminants and improving water quality.

- Tertiary Treatment:

- Advanced Oxidation Processes (AOP): Techniques such as ozonation or hydrogen peroxide oxidation are used to break down persistent organic contaminants and pharmaceutical residues.

- Disinfection: Ultraviolet (UV) light or ozone disinfection systems ensure that any remaining microorganisms are effectively inactivated.

- Special Considerations:

- Pharmaceutical Residues: Additional treatments may be required to address specific pharmaceutical residues, ensuring they are completely removed.

- Sludge Management: The sludge produced during treatment is dewatered and properly disposed of or further treated to minimize environmental impact.

Benefits of ETP Plants for Pharmaceuticals

- Regulatory Compliance: Ensures that pharmaceutical wastewater meets stringent regulatory standards before discharge, avoiding legal issues and potential fines.

- Environmental Protection: Effectively removes hazardous chemicals and pharmaceutical residues, protecting public health and the environment.

- Resource Efficiency: Treats and recycles wastewater efficiently, reducing the demand for fresh water and minimizing operational costs.

- Operational Efficiency: Provides a reliable and sustainable solution for wastewater management, enhancing the overall efficiency of pharmaceutical operations.

Conclusion

Effluent Treatment Plants (ETP) for the pharmaceutical industry are vital for managing the complex and potentially hazardous wastewater generated by pharmaceutical manufacturing processes. By employing a combination of physical, chemical, and biological treatment methods, these plants ensure high-quality treated water that meets regulatory standards.

Aquafit Technology offers advanced ETP solutions specifically designed for pharmaceutical facilities. Our state-of-the-art systems provide optimal performance, regulatory compliance, and environmental protection, helping you achieve effective and sustainable wastewater management.

ETP

Plant for Steel Rerolling Mills

Introduction

Effluent

Treatment Plants (ETP) tailored for steel rerolling mills are essential for

managing the substantial volumes of wastewater generated during the steel

manufacturing and rerolling processes. This wastewater often contains heavy

metals, oils, and other contaminants that require specialized treatment to meet

environmental standards and ensure safe disposal or reuse. Aquafit Technology

offers advanced ETP solutions designed to address the unique challenges of

steel rerolling mill wastewater in Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for steel rerolling mills are specialized systems designed to treat wastewater

produced from steel manufacturing and rerolling operations. These plants employ

a combination of physical, chemical, and biological processes to remove

contaminants and ensure that the treated water meets environmental regulations.

How

ETP Plants for Steel Rerolling Mills Work

- Pre-Treatment:

- Screening and

Filtration:

Initial stages involve removing large solids and debris from the

wastewater through screening and filtration processes.

- Oil and Grease

Removal:

Coalescers or centrifuges are used to separate and remove oils and

grease, which are commonly present in steel mill wastewater.

- Primary Treatment:

- Sedimentation: In sedimentation

tanks, suspended solids settle out from the wastewater, reducing the load

on subsequent treatment stages.

- Secondary

Treatment:

- Biological

Treatment:

Microorganisms break down organic contaminants in aerobic or anaerobic

reactors, such as Activated Sludge Process (ASP) or Moving Bed Biofilm

Reactor (MBBR). This step helps in treating the organic load and

improving water quality.

- Chemical

Precipitation:

Heavy metals and other pollutants are removed through chemical

precipitation processes, where chemicals are added to form insoluble

compounds that can be separated from the water.

- Tertiary Treatment:

- Advanced

Filtration:

Technologies like Ultrafiltration (UF) or Reverse Osmosis (RO) may be

used for further purification, removing remaining contaminants and

improving water quality.

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems are employed to kill any remaining

microorganisms and ensure the treated water is safe for discharge or

reuse.

- Sludge Management:

- Dewatering and

Disposal:

The sludge generated during treatment is dewatered and properly disposed

of or further processed to minimize environmental impact.

Benefits

of ETP Plants for Steel Rerolling Mills

- Regulatory

Compliance:

Ensures that steel mill wastewater meets stringent environmental

regulations before discharge, avoiding legal issues and potential fines.

- Environmental

Protection:

Effectively removes heavy metals, oils, and other contaminants, reducing

the impact on local water bodies and ecosystems.

- Resource

Efficiency:

Enables the recycling and reuse of treated water, reducing freshwater

consumption and operational costs.

- Operational

Efficiency:

Provides a reliable and sustainable solution for wastewater management,

enhancing the overall efficiency of steel rerolling mill operations.

Conclusion

Effluent

Treatment Plants (ETP) for steel rerolling mills are crucial for managing the

complex and potentially hazardous wastewater generated during steel

manufacturing. By employing a combination of physical, chemical, and biological

treatment processes, these plants ensure high-quality treated water that meets

regulatory standards.

Aquafit

Technology offers state-of-the-art ETP solutions specifically designed for

steel rerolling mills. Our advanced systems ensure optimal performance,

regulatory compliance, and environmental protection, helping you achieve

effective and sustainable wastewater management.

ETP

Plant for Paper Mills: Effective Solutions for Managing Wastewater

Introduction

Effluent

Treatment Plants (ETP) for paper mills are crucial for managing the diverse and

often challenging wastewater produced during paper manufacturing. The

wastewater from paper mills contains a variety of contaminants, including

organic matter, chemical additives, and fibers, which require specialized

treatment to ensure environmental compliance and sustainability. Aquafit

Technology provides advanced ETP solutions specifically designed to address the

unique needs of paper mills in Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for paper mills are systems engineered to treat wastewater generated during the

paper production process. These plants use a combination of physical, chemical,

and biological processes to remove contaminants and ensure that the treated

water meets environmental standards for discharge or reuse.

How

ETP Plants for Paper Mills Work

- Pre-Treatment:

- Screening and

Filtration:

Large solids, such as paper fibers and debris, are removed through

screening and filtration processes.

- Chemical Dosing: Coagulants and

flocculants are added to help aggregate fine particles and contaminants,

facilitating their removal.

- Primary Treatment:

- Sedimentation: Suspended solids

settle out in sedimentation tanks, reducing the organic and particulate

load on subsequent treatment stages.

- Secondary

Treatment:

- Biological

Treatment:

Microorganisms decompose organic matter in aerobic or anaerobic reactors,

such as Activated Sludge Process (ASP) or Moving Bed Biofilm Reactor

(MBBR). This step is crucial for breaking down biodegradable organic

contaminants.

- Chemical

Precipitation:

Heavy metals and other pollutants are removed through chemical

precipitation, where chemicals form insoluble compounds that can be

separated from the water.

- Tertiary Treatment:

- Advanced

Filtration:

Technologies like Ultrafiltration (UF) or Reverse Osmosis (RO) may be

used for further purification, removing remaining contaminants and

improving water quality.

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems ensure that any remaining

microorganisms are effectively inactivated, providing safe water for

discharge or reuse.

- Sludge Management:

- Dewatering and

Disposal:

The sludge generated during treatment is dewatered and properly disposed

of or further processed to minimize environmental impact.

Benefits

of ETP Plants for Paper Mills

- Regulatory

Compliance:

Ensures that paper mill wastewater meets stringent environmental

regulations before discharge, avoiding legal issues and potential fines.

- Environmental

Protection:

Effectively removes organic matter, chemical additives, and fibers,

reducing the impact on local water bodies and ecosystems.

- Resource

Efficiency:

Facilitates the recycling and reuse of treated water, reducing freshwater

consumption and operational costs.

- Operational

Efficiency:

Provides a reliable and sustainable solution for wastewater management,

enhancing the overall efficiency of paper mill operations.

Conclusion

Effluent

Treatment Plants (ETP) for paper mills are essential for managing the diverse

and often complex wastewater generated during paper manufacturing. By utilizing

a combination of physical, chemical, and biological treatment processes, these

plants ensure high-quality treated water that meets regulatory standards.

Aquafit

Technology offers state-of-the-art ETP solutions tailored for paper mills. Our

advanced systems ensure optimal performance, regulatory compliance, and

environmental protection, helping you achieve effective and sustainable

wastewater management.

ETP

Plant for Printing and Press

Introduction

Effluent

Treatment Plants (ETP) for printing and press industries are essential for

managing the diverse and often challenging wastewater generated from printing

processes. This wastewater typically contains inks, solvents, and various

chemical additives that require specialized treatment to ensure environmental

compliance and sustainability. Aquafit Technology provides advanced ETP

solutions tailored to the unique needs of printing and press facilities in

Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for printing and press industries are designed to treat wastewater produced

during printing and press operations. These plants utilize a combination of

physical, chemical, and biological processes to remove contaminants and ensure

that the treated water meets environmental standards for discharge or reuse.

How

ETP Plants for Printing and Press Work

- Pre-Treatment:

- Screening and

Filtration:

Large solids, such as paper fibers and debris, are removed through

screening and filtration processes.

- Oil and Grease

Removal:

Coalescers or separators are used to remove oils, greases, and solvents

commonly found in printing wastewater.

- Primary Treatment:

- Sedimentation: Suspended solids

settle out in sedimentation tanks, reducing the load on subsequent

treatment stages and removing larger particles.

- Secondary

Treatment:

- Biological

Treatment:

In aerobic or anaerobic reactors, microorganisms decompose organic

contaminants, including residual inks and chemicals, using processes like

Activated Sludge Process (ASP) or Moving Bed Biofilm Reactor (MBBR).

- Chemical

Precipitation:

Heavy metals and other pollutants are removed through chemical

precipitation, where chemicals are added to form insoluble compounds that

can be separated from the water.

- Tertiary Treatment:

- Advanced

Filtration:

Technologies such as Ultrafiltration (UF) or Reverse Osmosis (RO) may be

used to further purify the water, removing any remaining contaminants and

improving water quality.

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems ensure that any remaining

microorganisms are effectively inactivated, providing safe water for

discharge or reuse.

- Special

Considerations:

- Ink Residues: Additional

treatments, such as advanced oxidation processes (AOP) or activated

carbon adsorption, may be necessary to address specific ink residues and

chemical pollutants.

- Sludge Management: The sludge

generated during treatment is dewatered and properly disposed of or

further processed to minimize environmental impact.

Benefits

of ETP Plants for Printing and Press

- Regulatory

Compliance:

Ensures that wastewater from printing and press operations meets stringent

environmental regulations before discharge, avoiding legal issues and

potential fines.

- Environmental

Protection:

Effectively removes inks, solvents, and other contaminants, reducing the

impact on local water bodies and ecosystems.

- Resource

Efficiency:

Facilitates the recycling and reuse of treated water, reducing freshwater

consumption and operational costs.

- Operational

Efficiency:

Provides a reliable and sustainable solution for wastewater management,

enhancing the overall efficiency of printing and press operations.

Conclusion

Effluent

Treatment Plants (ETP) for printing and press industries are vital for managing

the diverse and potentially hazardous wastewater generated during printing

processes. By employing a combination of physical, chemical, and biological

treatment processes, these plants ensure high-quality treated water that meets

regulatory standards.

Aquafit

Technology offers state-of-the-art ETP solutions specifically designed for the

printing and press industry. Our advanced systems ensure optimal performance,

regulatory compliance, and environmental protection, helping you achieve

effective and sustainable wastewater management.

ETP

Plant for Auto Rice Mills

Introduction

Effluent

Treatment Plants (ETP) for auto rice mills are crucial for managing the

wastewater generated during rice milling processes. This wastewater often

contains organic matter, starch, and other contaminants that require

specialized treatment to ensure environmental compliance and sustainability.

Aquafit Technology provides advanced ETP solutions specifically designed to

address the unique needs of auto rice mills in Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for auto rice mills are systems designed to treat wastewater produced during

rice milling operations. These plants utilize a combination of physical,

chemical, and biological processes to remove contaminants and ensure that the

treated water meets environmental standards for discharge or reuse.

How

ETP Plants for Auto Rice Mills Work

- Pre-Treatment:

- Screening and

Filtration:

Initial stages involve removing large solids and debris, such as husks

and fibers, through screening and filtration processes.

- Oil and Grease

Removal:

Coalescers or separators may be used to remove oils and greases from the

wastewater.

- Primary Treatment:

- Sedimentation: Suspended solids,

including rice bran and starch, settle out in sedimentation tanks. This

step reduces the load on subsequent treatment stages by removing larger

particles.

- Secondary

Treatment:

- Biological

Treatment:

Microorganisms decompose organic matter in aerobic or anaerobic reactors,

such as Activated Sludge Process (ASP) or Moving Bed Biofilm Reactor

(MBBR). This step is crucial for breaking down biodegradable organic

contaminants.

- Chemical

Precipitation:

Additional treatment may involve adding chemicals to precipitate heavy

metals and other pollutants that may be present in the wastewater.

- Tertiary Treatment:

- Advanced

Filtration:

Technologies like Ultrafiltration (UF) or Reverse Osmosis (RO) may be

used for further purification, removing any remaining contaminants and

improving water quality.

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems are employed to ensure that any

remaining microorganisms are effectively inactivated, providing safe

water for discharge or reuse.

- Sludge Management:

- Dewatering and

Disposal:

The sludge generated during treatment is dewatered and properly disposed

of or further processed to minimize environmental impact.

Benefits

of ETP Plants for Auto Rice Mills

- Regulatory

Compliance:

Ensures that wastewater from auto rice mills meets stringent environmental

regulations before discharge, avoiding legal issues and potential fines.

- Environmental

Protection:

Effectively removes organic matter, starch, and other contaminants,

reducing the impact on local water bodies and ecosystems.

- Resource

Efficiency:

Enables the recycling and reuse of treated water, reducing freshwater

consumption and operational costs.

- Operational

Efficiency:

Provides a reliable and sustainable solution for wastewater management,

enhancing the overall efficiency of rice milling operations.

Conclusion

Effluent

Treatment Plants (ETP) for auto rice mills are essential for managing the

wastewater generated during rice milling processes. By utilizing a combination

of physical, chemical, and biological treatment methods, these plants ensure

high-quality treated water that meets regulatory standards.

Aquafit

Technology offers cutting-edge ETP solutions tailored for auto rice mills. Our

advanced systems provide optimal performance, regulatory compliance, and

environmental protection, helping you achieve effective and sustainable

wastewater management.

ETP

Plant for Oil and Grease Waste

Introduction

Effluent

Treatment Plants (ETP) for oil and grease waste are essential for managing the

complex wastewater generated from industries such as food processing,

automotive, and manufacturing. Oil and grease waste poses significant

challenges due to its high pollutant load and potential environmental impact.

Aquafit Technology provides advanced ETP solutions specifically designed to

address these challenges and ensure effective treatment of oil and grease

waste.

Definition

Effluent

Treatment Plants (ETP)

for oil and grease waste are specialized systems designed to treat wastewater

containing high concentrations of oils, greases, and other contaminants. These

plants use a combination of physical, chemical, and biological processes to

remove pollutants and ensure that the treated water meets environmental

discharge standards.

How

ETP Plants for Oil and Grease Waste Work

- Pre-Treatment:

- Screening and

Filtration:

Large solids and debris, such as sludge and particulate matter, are

removed through screening and filtration processes.

- Oil-Water

Separation:

Coalescers or gravity separators are used to separate and remove oils and

greases from the wastewater. This step is crucial for reducing the load

on subsequent treatment stages.

- Primary Treatment:

- Sedimentation: In sedimentation

tanks, suspended solids and remaining oil droplets settle out, further

reducing the pollutant load and improving the efficiency of secondary

treatment.

- Secondary

Treatment:

- Biological

Treatment:

In aerobic or anaerobic reactors, microorganisms decompose remaining

organic contaminants. Processes like Activated Sludge Process (ASP) or

Moving Bed Biofilm Reactor (MBBR) help break down biodegradable oils and

greases.

- Chemical Dosing: Coagulants and

flocculants may be added to aid in the removal of fine particles and

emulsified oils, facilitating their separation from the water.

- Tertiary Treatment:

- Advanced

Filtration:

Technologies such as Ultrafiltration (UF) or Reverse Osmosis (RO) may be

employed for further purification, removing any remaining contaminants

and ensuring high-quality treated water.

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems are used to eliminate any remaining

microorganisms and ensure that the treated water is safe for discharge or

reuse.

- Sludge Management:

- Dewatering and

Disposal:

The sludge generated during treatment is dewatered and properly disposed

of or further processed to minimize environmental impact.

Benefits

of ETP Plants for Oil and Grease Waste

- Regulatory

Compliance:

Ensures that wastewater containing oils and greases meets environmental

regulations before discharge, avoiding legal issues and potential fines.

- Environmental

Protection:

Effectively removes oils, greases, and other contaminants, reducing the

impact on local water bodies and ecosystems.

- Resource

Efficiency:

Facilitates the recycling and reuse of treated water, reducing freshwater

consumption and operational costs.

- Operational

Efficiency:

Provides a reliable and sustainable solution for wastewater management,

enhancing the overall efficiency of industrial operations.

Conclusion

Effluent

Treatment Plants (ETP) for oil and grease waste are vital for managing

wastewater with high concentrations of oils and greases. By employing a

combination of physical, chemical, and biological treatment processes, these plants

ensure that the treated water meets regulatory standards and minimizes

environmental impact.

Aquafit

Technology offers cutting-edge ETP solutions designed specifically for handling

oil and grease waste. Our advanced systems provide optimal performance,

regulatory compliance, and environmental protection, helping you achieve

effective and sustainable wastewater management.

ETP

Plant for Dairy Farms and Cattle Houses

Introduction

Effluent

Treatment Plants (ETP) for dairy farms and cattle houses play a crucial role in

managing the substantial volumes of wastewater generated from dairy and

livestock operations. This wastewater often contains high levels of organic

matter, nutrients, and other contaminants that require effective treatment to

ensure environmental compliance and sustainability. Aquafit Technology provides

advanced ETP solutions tailored to the unique needs of dairy farms and cattle

houses in Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for dairy farms and cattle houses are specialized systems designed to treat

wastewater produced from dairy and livestock operations. These plants utilize a

combination of physical, chemical, and biological processes to remove

contaminants and ensure that the treated water meets environmental discharge

standards.

How

ETP Plants for Dairy Farms and Cattle Houses Work

- Pre-Treatment:

- Screening and

Filtration:

Large solids such as manure, straw, and feed residues are removed through

screening and filtration processes.

- Settling Tanks: Initial settling

tanks help to separate larger solids from the wastewater, reducing the

load on subsequent treatment stages.

- Primary Treatment:

- Sedimentation: In sedimentation

tanks, suspended solids and heavier particles settle out. This step helps

reduce the organic and particulate load on secondary treatment processes.

- Secondary

Treatment:

- Biological

Treatment:

Microorganisms decompose organic contaminants in aerobic or anaerobic

reactors. Processes like Activated Sludge Process (ASP) or Moving Bed

Biofilm Reactor (MBBR) are used to treat the high organic load and

nutrients present in dairy and cattle wastewater.

- Nutrient Removal: Specialized

processes, such as nitrification-denitrification, are used to remove

excess nutrients like nitrogen and phosphorus, which can cause

environmental issues if discharged untreated.

- Tertiary Treatment:

- Advanced

Filtration:

Technologies such as Ultrafiltration (UF) or Reverse Osmosis (RO) can be

employed for further purification, removing remaining contaminants and

ensuring high-quality treated water.

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems are used to ensure that any remaining

microorganisms are effectively inactivated, providing safe water for

discharge or reuse.

- Sludge Management:

- Dewatering and

Disposal:

The sludge generated during treatment is dewatered and properly disposed

of or further processed to reduce its volume and minimize environmental

impact.

Benefits

of ETP Plants for Dairy Farms and Cattle Houses

- Regulatory

Compliance:

Ensures that wastewater from dairy farms and cattle houses meets

environmental regulations before discharge, avoiding legal issues and

potential fines.

- Environmental

Protection:

Effectively removes organic matter, nutrients, and other contaminants,

reducing the impact on local water bodies and ecosystems.

- Resource

Efficiency:

Facilitates the recycling and reuse of treated water, reducing freshwater

consumption and operational costs.

- Operational

Efficiency:

Provides a reliable and sustainable solution for wastewater management,

enhancing the overall efficiency of dairy and livestock operations.

Conclusion

Effluent

Treatment Plants (ETP) for dairy farms and cattle houses are essential for

managing the complex wastewater generated from these operations. By employing a

combination of physical, chemical, and biological treatment methods, these

plants ensure high-quality treated water that meets regulatory standards and

minimizes environmental impact.

Aquafit

Technology offers state-of-the-art ETP solutions specifically designed for

dairy farms and cattle houses. Our advanced systems ensure optimal performance,

regulatory compliance, and environmental protection, helping you achieve

effective and sustainable wastewater management.

ETP

Plant for Apartment Wastewater

Introduction

Effluent

Treatment Plants (ETP) for apartment wastewater are essential for managing the

wastewater generated from residential buildings. With the increasing density of

urban areas, managing wastewater effectively has become a critical aspect of

sustainable living. Aquafit Technology provides advanced ETP solutions designed

to address the unique challenges of treating wastewater from apartment

complexes in Bangladesh.

Definition

Effluent

Treatment Plants (ETP)

for apartment wastewater are systems designed to treat the wastewater produced

by residential buildings. These plants use a combination of physical, chemical,

and biological processes to remove contaminants and ensure that the treated

water meets environmental standards for discharge or reuse.

How

ETP Plants for Apartment Wastewater Work

- Pre-Treatment:

- Screening and

Filtration:

Large solids, such as paper, plastics, and other debris, are removed

through screening and filtration processes.

- Grease Traps: Grease and oils

from kitchen wastewater are captured in grease traps to prevent them from

interfering with the treatment process.

- Primary Treatment:

- Sedimentation: In primary

sedimentation tanks, suspended solids settle out, reducing the load on

subsequent treatment stages and removing larger particles from the

wastewater.

- Secondary

Treatment:

- Biological

Treatment:

Microorganisms break down organic contaminants in aerobic or anaerobic

reactors. Common processes include Activated Sludge Process (ASP) or

Moving Bed Biofilm Reactor (MBBR), which treat the organic load and

ensure effective decomposition of pollutants.

- Nutrient Removal: Techniques like

nitrification-denitrification may be employed to remove excess nutrients

such as nitrogen and phosphorus, which can contribute to environmental

pollution if not adequately treated.

- Tertiary Treatment:

- Advanced

Filtration:

Technologies such as Ultrafiltration (UF) or Reverse Osmosis (RO) are

used for further purification, removing any remaining contaminants and

ensuring high-quality treated water.

- Disinfection: Ultraviolet (UV)

light or ozone disinfection systems are used to ensure that any remaining

microorganisms are effectively inactivated, providing safe water for

discharge or potential reuse.

- Sludge Management:

- Dewatering and

Disposal:

The sludge generated during treatment is dewatered and either disposed of

or processed further to reduce its volume and environmental impact.

Benefits

of ETP Plants for Apartment Wastewater

- Regulatory

Compliance:

Ensures that wastewater from apartment complexes meets stringent

environmental regulations before discharge, avoiding legal issues and

potential fines.

- Environmental

Protection:

Effectively removes organic matter, nutrients, and contaminants, reducing

the impact on local water bodies and ecosystems.

- Resource

Efficiency:

Facilitates the recycling and reuse of treated water, which can be used

for non-potable purposes such as irrigation, reducing freshwater

consumption and operational costs.

- Operational

Efficiency:

Provides a reliable and sustainable solution for managing residential

wastewater, enhancing the overall efficiency of apartment complexes.

Conclusion

Effluent

Treatment Plants (ETP) for apartment wastewater are crucial for managing the

diverse and potentially challenging wastewater generated from residential

buildings. By employing a combination of physical, chemical, and biological

treatment processes, these plants ensure high-quality treated water that meets

regulatory standards and minimizes environmental impact.

Aquafit

Technology offers advanced ETP solutions specifically designed for apartment

complexes. Our state-of-the-art systems provide optimal performance, regulatory

compliance, and environmental protection, helping you achieve effective and

sustainable wastewater management for residential buildings.